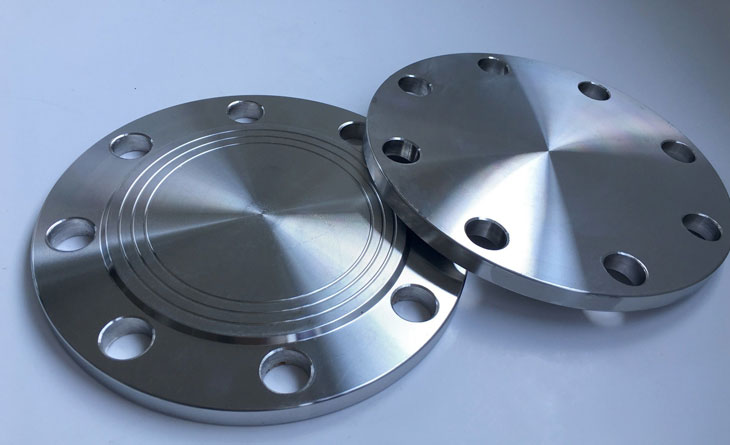

Blind Flanges

Blind flanges are solid flanges without a bore, used to seal off piping systems or vessel openings, preventing leaks and enabling easy access for inspections. They can be supplied with or without hubs, depending on manufacturer specifications.

These flanges are critical for safely isolating sections of pipelines or equipment, widely used in industries like oil and gas, chemical processing, and power generation for their reliability and accessibility.

Blind flanges serve as robust closures for piping systems or vessel openings, designed without a central bore to block flow and maintain system integrity. They facilitate maintenance by allowing easy access for inspection or cleaning when removed. Available with or without hubs, blind flanges are versatile components that can withstand high pressure and harsh conditions, making them essential for isolating pipelines or equipment during operation or shutdowns.

Blind flanges are manufactured to meet stringent industry standards, ensuring compatibility and performance in various applications.

| Grade/Standard | Equivalent | Application |

|---|---|---|

| ASTM A105, ANSI B16.5 | Carbon Steel | Oil and gas, general piping |

| ASTM A182 F304/F316 | Stainless Steel | Chemical processing, marine |

| ASTM A350 LF2 | Low-Temperature Carbon Steel | Cryogenic pipelines |

Blind flanges are vital in industries requiring secure closures and easy access for piping systems:

| Properties | Values & Limits |

|---|---|

| Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Standards | ASME B16.5, ANSI B16.47, MSS-SP-44 |

| Type | With or Without Hubs |

| Size Range | 1/2" to 24" (Standard), up to 60" (Custom) |

| Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500# |