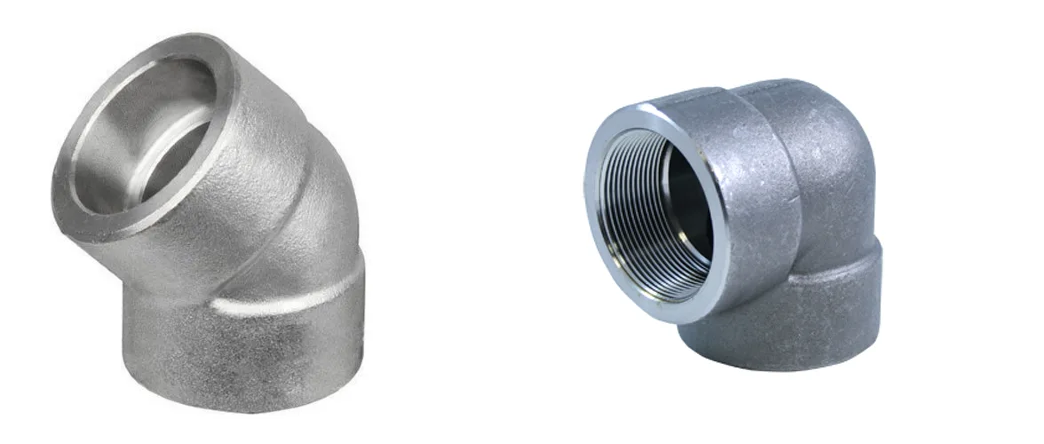

ELBOW 45° & 90°

ELBOW 45° and ELBOW 90° are essential pipe fittings used to connect pipes, enabling a change in the direction of flow at 45 or 90 degrees. These fittings ensure efficient fluid or gas transport in piping systems across various industries.

ELBOW 45° and ELBOW 90° are critical components in piping systems, allowing for directional changes while maintaining structural integrity. Available in materials like carbon steel, stainless steel, and alloy steel, they are designed to meet diverse pressure, temperature, and corrosion requirements.

ELBOW 45° and ELBOW 90° are indispensable in creating efficient and flexible piping networks. The 45° elbow allows for a gentler change in direction, reducing flow resistance, while the 90° elbow is ideal for sharp turns in confined spaces. These fittings are manufactured in seamless or welded forms, with materials and dimensions tailored to specific industrial standards.

ELBOW 45° and ELBOW 90° are categorized based on angle, material, and connection type to meet specific application needs.

| Type | Description | Application |

|---|---|---|

| ELBOW 45° | Facilitates a 45-degree change in pipe direction, reducing flow turbulence. | Water supply, HVAC, and low-pressure systems. |

| ELBOW 90° | Enables a sharp 90-degree turn, ideal for compact layouts. | Oil and gas, chemical processing, and plumbing. |

| Long Radius (LR) Elbow | Has a larger radius, minimizing flow resistance and wear. | High-flow systems like pipelines and refineries. |

| Short Radius (SR) Elbow | Compact design with a shorter radius, suitable for tight spaces. | Space-constrained industrial applications. |

ELBOW 45° and ELBOW 90° are widely used across industries due to their ability to adapt piping systems to complex layouts:

| Properties | Values & Limits |

|---|---|

| Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Size | 1/2" to 48" |

| Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Standards | ASME B16.9, ANSI, API, DIN, JIS |

| Surface Finish | Black, Galvanized, Anti-corrosion Coated |