HIPPS

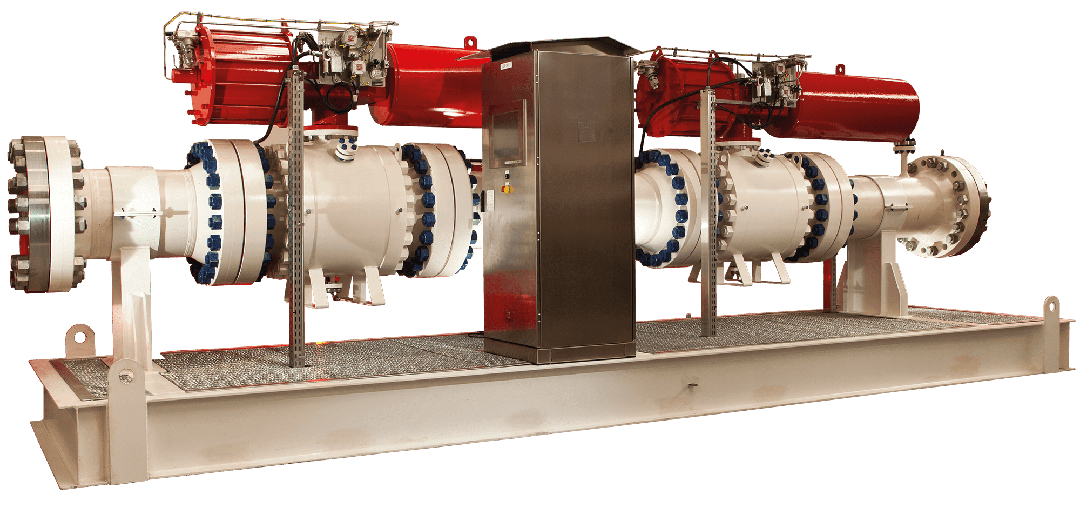

HIPPS (High-Integrity Pressure Protection System) is a safety instrumented system designed to prevent over-pressurization in industrial plants by automatically isolating pressure sources when unsafe conditions are detected.

These critical safety systems provide an alternative to traditional mechanical relief devices, offering faster response times and greater reliability in oil refineries, chemical plants, and other high-pressure processing facilities.

HIPPS represents the highest level of safety integrity for pressure protection, combining sensors, logic solvers, and final control elements to form a complete safety loop. When pressure exceeds predetermined safe limits, the system rapidly closes isolation valves to prevent equipment damage or hazardous releases. Unlike conventional pressure relief valves that vent excess pressure, HIPPS maintains process containment, making it ideal for handling toxic, flammable, or environmentally sensitive materials. These systems are designed to meet rigorous SIL (Safety Integrity Level) requirements, with redundant components and continuous self-testing to ensure maximum reliability.

A complete HIPPS consists of multiple integrated components working together to provide comprehensive overpressure protection:

| Component | Function | Typical Specifications |

|---|---|---|

| Pressure Sensors | Detect overpressure conditions | Redundant transmitters, ±0.1% accuracy |

| Logic Solver | Processes signals and initiates shutdown | SIL 3 certified, 2oo3 voting |

| Isolation Valves | Block flow when activated | Ball or gate valves, <100ms closure |

| Diagnostic Module | Continuous system health monitoring | 90-99% diagnostic coverage |

| Alarm Panel | Provides operator interface | HMI with event logging |

HIPPS are deployed in critical applications where conventional pressure relief is inadequate or undesirable:

| Parameter | Specification |

|---|---|

| Safety Integrity Level | SIL 2 or SIL 3 (IEC 61508/61511) |

| Response Time | <100ms to full closure |

| Pressure Range | Up to 25,000 psi (1,725 bar) |

| Temperature Range | -50°C to 450°C (-58°F to 842°F) |

| Voting Logic | 1oo1, 1oo2, 2oo3 configurations |

| Certifications | IEC 61508, IEC 61511, API 521, ASME |

| Materials | Carbon steel, stainless steel, alloy materials |

| Communication Protocols | HART, Modbus, Foundation Fieldbus, PROFIBUS |