Flanges Category

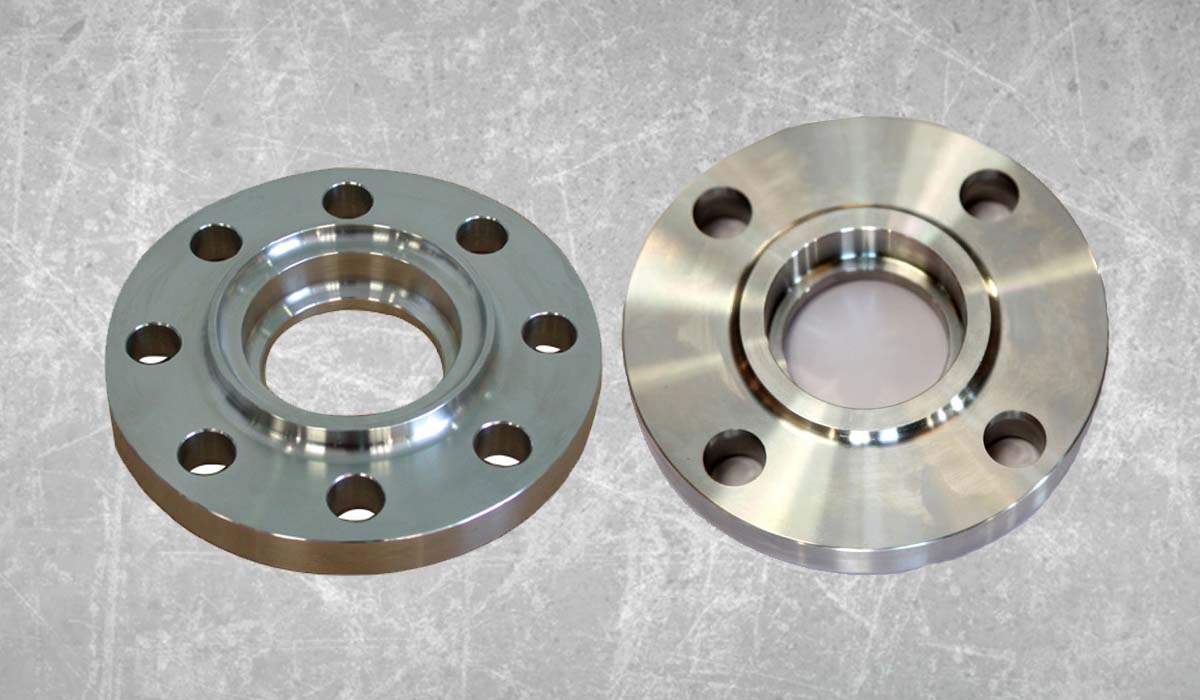

Flanges are critical components used to connect pipes, valves, pumps and other equipment in piping systems. Available in materials like carbon steel, alloy steel, and stainless steel, they provide easy access for cleaning, inspection, and modification of piping networks.

Flanges create strong, leak-proof connections that can withstand high pressure and temperature. Their various types and facing options make them suitable for diverse industrial applications, from oil and gas to water treatment and chemical processing.

Pipe flanges form secure connections between piping components while allowing for disassembly when needed. Whether weld neck, slip-on, or blind type, they are manufactured to precise standards ensuring proper sealing and alignment. Explore our range of Weld Neck Flanges, Slip-On Flanges, and Blind Flanges for detailed specifications.

Flanges are categorized based on their attachment method, face type, and pressure class to meet specific system requirements.

| Type | Description | Application |

|---|---|---|

| Weld Neck Flanges | Butt-welded to pipe for high-integrity connections in critical systems. | High-pressure/temperature systems, hazardous fluids |

| Slip-On Flanges | Slips over pipe and welded both inside and outside for easy alignment. | Low-pressure systems, cost-effective solutions |

| Blind Flanges | Used to seal ends of piping systems or vessel openings. | System isolation, pressure testing, future expansion |

| Socket Weld Flanges | Pipe inserts into socket for compact, high-strength connections. | Small-bore, high-pressure systems |

| Lap Joint Flanges | Used with stub ends for systems requiring frequent disassembly. | Systems requiring regular maintenance/inspection |

| Threaded Flanges | Internal threads screw onto external pipe threads without welding. | Low-pressure systems, explosive areas where welding is unsafe |

Flanges are essential components across industries for creating secure and maintainable piping connections:

| Properties | Values |

|---|---|

| Material | Carbon Steel (A105), Alloy Steel (F11, F22), Stainless Steel (304, 316, 316L) |

| Size Range | 1/2" to 60" (varies by type) |

| Pressure Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Face Types | Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ) |

| Standards | ASME B16.5, ASME B16.47, API 6A, AWWA, DIN |

| Surface Finish | Black, Galvanized, Anti-corrosion Coated, Polished (for SS) |