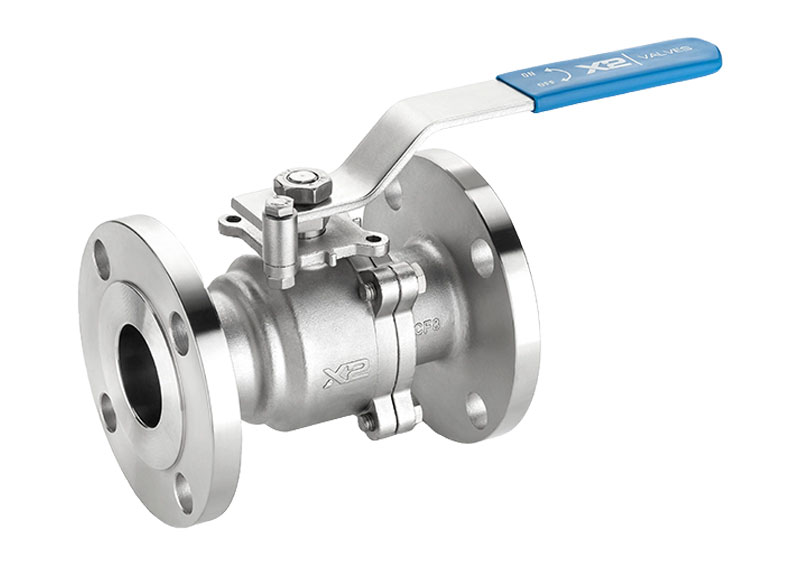

Ball Valves

Ball valves are quarter-turn valves that use a pivoting, perforated ball to control fluid flow, offering quick and reliable shut-off with minimal pressure drop.

Available in floating and trunnion-mounted designs, ball valves are widely used in industries such as oil and gas, petrochemical, and water treatment for their durability and ease of operation.

Ball valves operate by rotating a hollow, perforated ball 90 degrees to align or misalign the ball's hole with the flow path, enabling efficient on-off control. Floating ball valves, designed to BS5351, are ideal for smaller sizes, while trunnion-mounted valves, per API 6D, support larger, high-pressure applications. Their compact design, low maintenance, and ability to handle various fluids make them a preferred choice in critical industrial systems.

Ball valves are manufactured to meet stringent industry standards, ensuring reliability and compatibility in various systems.

| Type/Standard | Material | Application |

|---|---|---|

| Floating Ball: BS5351 | 4130, 410, A487 4C, CA15, CF8M | Oil and gas, water treatment |

| Trunnion Mounted: API 6D | Duplex, Super Duplex, Inconel | High-pressure, large-diameter systems |

Ball valves are critical in industries requiring efficient and reliable flow control:

| Properties | Values & Limits |

|---|---|

| Material | 4130, 410, A487 4C, CA15, CF8M, Duplex, Super Duplex, Inconel |

| Design Standards | API 6A, ASME VIII, API 6FA, API 6D, BS5351 |

| Connection | RF, RTJ, Flanged, Welded |

| Size Range | 1/2" to 2" (Floating, ANSI 1500); 3" to 12" (Floating, ANSI 600); 2" to 56" (Trunnion, ANSI 1500); 2 1/16" to 4 1/16" (API 6A) |

| Pressure Rating | Up to ANSI Class 1500 lbs; 2000–10,000 PSI (API 6A) |

| Face to Face | API 6D, ASME B16.10 |

| Testing Standards | API 6A, ISO 5208 |

| Flange Details | ASME B16.5, API 6A |

| Product Spec Level | PSL 1, 2, 3, 3G, 4 |

| Trims | API Class AA to HH, TCC Coated Seats |