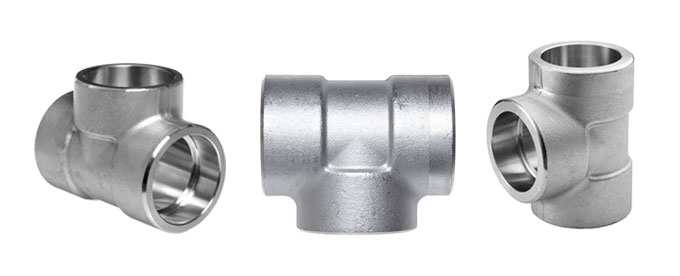

TEES

Tees are vital pipe fittings designed to connect three pipes, forming a "T" shape to branch or combine fluid or gas flow in piping systems. Typically made from the same material as the connected pipes, such as copper, steel, or PVC, they ensure compatibility and structural integrity.

Tees facilitate efficient flow distribution in plumbing and industrial systems, available in various materials to meet specific pressure, temperature, and corrosion requirements. Their versatile design supports both equal and reducing configurations for diverse applications.

Tees are essential components in creating complex piping networks, allowing for the connection of three pipes to either split or merge flow. Manufactured in materials like copper, steel, and PVC to match the piping system, they are available in welded, threaded, or solvent-welded forms, tailored to industry standards for reliable performance.

Tees are categorized based on their configuration, material, and connection type to suit specific application needs.

| Type | Description | Application |

|---|---|---|

| Equal Tee | All three outlets have the same diameter, ensuring uniform flow. | Plumbing, HVAC, and industrial piping. |

| Reducing Tee | Branch outlet has a smaller diameter than the main run. | Systems requiring flow reduction, such as water distribution. |

| Copper Tee | Corrosion-resistant, ideal for water and gas systems. | Residential and commercial plumbing. |

| PVC Tee | Lightweight and corrosion-resistant, used in non-pressurized systems. | Drainage and irrigation systems. |

Tees are widely used across industries due to their ability to manage flow distribution in piping systems:

| Properties | Values & Limits |

|---|---|

| Material | Copper, Steel, PVC, Stainless Steel, Alloy Steel |

| Size | 1/8" to 48" |

| Pressure Rating | 150#, 300#, 600#, 900#, 1500# |

| Standards | ASME B16.9, ASME B16.11, ANSI, ASTM, DIN |

| Surface Finish | Galvanized, Polished, Anti-corrosion Coated, Solvent-Welded |